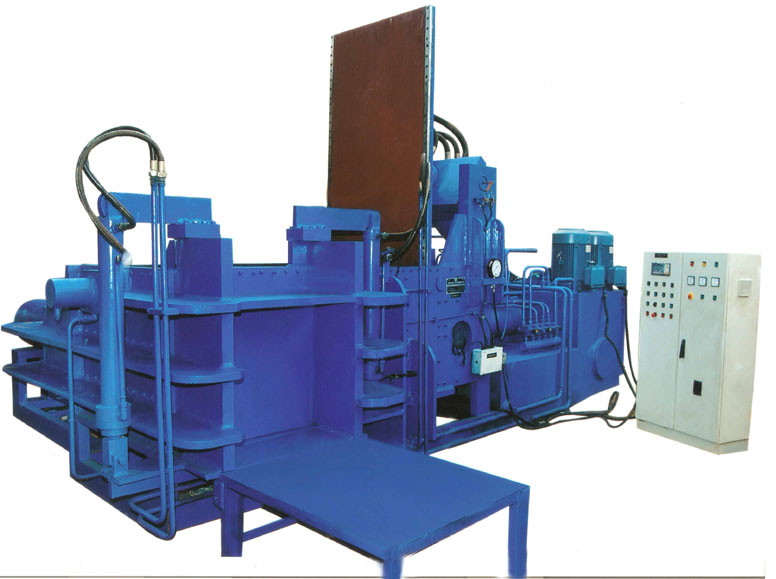

Our Triple Compression Baling Presses have a reputation of excellence for their quality, workmanship and reliability Since 1984. These presses are available in Triple Compression. They are suitable for all types of ferrous and non-ferrous light metal scrap material such as Stainless steel, M.S. scrap, aluminium, brass, copper and other industrial tin sheets.

Also Big chamber size baling press available for Automobile waste like:- car bodies, jeep, scooter, auto rikshaw and other automobile scrap waste.

Salient common features :-

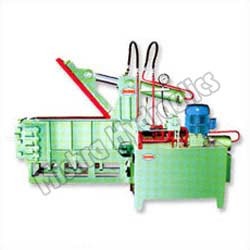

It has a Hydraulic Ejector system. Equipped with four cylinders. Our presses are available in double compression (with ejector cylinder, manual door & auto door). These are suited for all types of ferrous and non-ferrous light metal scrap material including stainless steel, MS scrap, aluminium, brass, copper and other industrial tin sheets.

Suitable for turning scrap

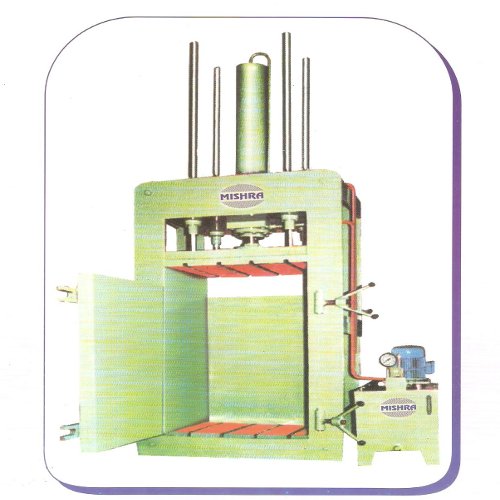

Vertical Baling Press for Book-Binders for handling of waste paper/corrugated boards, stationery (shreded and unshreded), plastic / fill waste etc. Ideally suited for the pressing of Paper waste, Corrugated boards, Stationery etc. and manually bundling the pressed bales for saving in storage space, transportation and manpower.

Our vertical baling presses are known for their quality, workmanship and reliability since 1984. Our presses are available in single compression. These presses are capable of compressing various leftovers metal structural, hdpe/pp woven sack bags and wooden waste.

Our Double Compression Baling Press is known for excellence in its quality, workmanship and reliability since 1984. Our presses are available in double compression (with ejector cylinder, manual door). These are suited for all types of ferrous and non-ferrous light metal scrap material including stainless steel, MS scrap, aluminium, brass, copper and other industrial tin sheets.

Our Triple Compression Baling Presses have a reputation of excellence for their quality, workmanship and reliability Since 1984. These presses are available in Triple Compression. They are suitable for all types of ferrous and non-ferrous light metal scrap material such as stainless steel, M.S. scrap, aluminium, brass, copper and other industrial tin sheets.